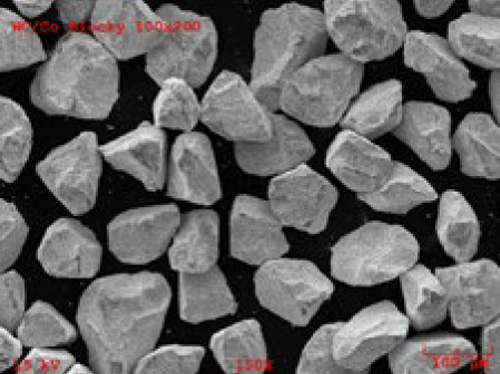

WC/Co-Crushed cemented carbide (CSC) is manufactured from used tooling that is comprised of micron sized WC bound by cobalt. Surface Engineering CSC is crushed from straight grade stock to ensure the wettability of the particles during application. During crushing, these particles yield two shapes, blocky and non-blocky (flats and slivers). Blocky particles in coarse sizes are used for cutting applications, fine sizes for packing density. Non-blocky particles are used to prevent general wear. CSC is extremely good at resisting impact and has moderate thermal properties. A full range of sizing from 1/4 US Mesh to 15 micron is commonly used for wear rate enhancement in applications like PTA, laser, MIG, tube rod, spray fuse, composite rod, drop systems and infiltration.

Thermal Properties: Moderate

Hardness: 1600 – 2000 HVN

Cobalt: 5.5 to 9.5%

Carbon Content: 5.4 – 5.9%