Surface Engineering’s Velocity Line

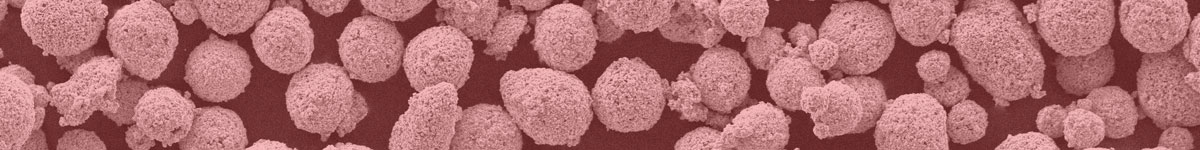

HVOF powders designed to provide optimum coating performance and application efficiency. Micron and /or sub-micron carbide powders combined with various metal binders are blended and unified in an attrition mill for hours before being agglomerated into spherical particles via spray drying. The milled feedstock adds toughness and corrosion resistance to the coating due to the uniform distribution of the binder within the high carbide content.

Further, the powders are sintered at temperatures just below the brick forming threshold to fully densify each particle increasing the thermal conductivity and hence, the deposit efficiency of our powders. And finally, the sintered powders are carefully screened to remove super-fines and have sizing properly matched to the thermal capacity of the spraying equipment enhancing the deposit efficiency and minimizing barrel/nozzle loading problems.

Micro-Velocity

The Micro-Velocity line is our commercially standard version whereby the grain size of our raw material ranges from two to five microns (1 to 2 tenths of a thousandth). These powders provide coatings that will likely perform superior than other due to the manufacturing process of the powder. They are priced to be competitive with others on the market, however, focus is placed on the “cost per pound deposited” rather per pound or kilogram.

Nano-Velocity

The Nano-Velocity line is our group of uniquely formulated compositions incorporating standard micron sized carbides (2-5um) with sub-micron sized (0.2 -0.5um / 200-500 nanometers). Coatings produced with these powders provide a higher “carbide to binder” surface area ratio than our micro-velocity coatings and up to a 30 percent increase in abrasion and erosion resistance can be expected, especially when resisting wear caused by sub-micron abrasives. Impact toughness and anti-roughening are other positive attributes of the coatings.

| Composition | Micro Velocity | G65* | Nano Velocity | G65* | Hardness Hv |

|---|---|---|---|---|---|

| 8812 WcCo | 2400 | 5.5 | 2400NV | 4.0 | 1050-1350 |

| 86-10-4 WcCoCr | 2404 | 5.8 | 2404NV | 4.2 | 1025-1350 |

| 8317 WcCo | 7301 | 6.5 | 7310NV | 5 | 950-1300 |

| 85-12-3 WcNiCr | 8515NCr | 6 | Custom | 950-1300 | |

| 9010N WcNi | 9010N | 5.2 | Custom | 1025-1350 | |

| 8515N WcNi | 8515N | 6 | Custom | 975-1250 | |

| 2435 WcCrNi | 2435 | 4.8 | Custom | 1100-1400 | |

| 6520 CrWcNiCr | x | 6520NV | 8.5 | 850-1050 | |

| 4540 CrWcNiCr | x | 4540NV | 7.0 | 875-1100 | |

| 7525Cr2C3NiCr | 3500 | 22 | x | 775-900 |

*ASTM G65 test procedure A: cubic millimeters volume loss