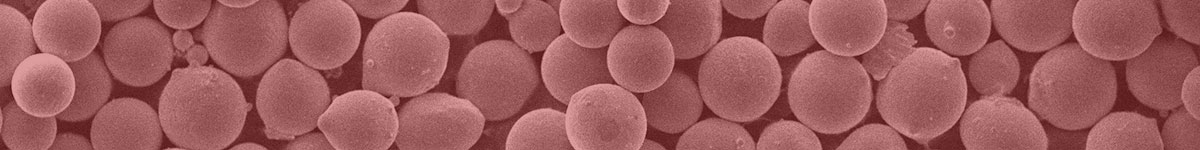

Surface Engineering’s SPECIALLOY nickel based alloy powders, rods and wires are commonly used for HVOF, LASER, Spray Fuse, PTA, and other hardfacing applications. Over the last 25 years, Surface Engineering has developed a full line of self-fluxing nickel alloys for hard surfacing, coating, and brazing. The SPECIALLOY family of alloys provides options to enhance wear and corrosion resistance on surfaces exposed to any variety of challenging environments.

Surface Engineering’s SPECIALLOY line of self-fluxing nickel alloys range in hardness from 15 to 65 HRC and are used for hard surfacing, coating, and brazing. These alloys provide a full range of solutions for corrosion, abrasion, erosion, impact and cavitation or combinations of wear modes. SPECIALLOY alloys see little or no change in hardness and toughness during thermal cycling from heat treating, making them a user-friendly solution and a superior solution to iron-based materials.

Higher hardness alloys are resistant to the harshest corrosive environments while at the same time providing hot hardness, erosion, abrasion, and oxidation resistance. This makes these alloys ideal for coating bushings, sleeves, and bearings for protection from corrosion and abradants in low impact situations.

Mid hardness alloys are an excellent choice when moderate impact is probable and corrosion, erosion and abrasion resistance is required. A number of these alloys are incorporated into our CARBORIDE line of products where SPECIALLOY nickel alloys are compounded with tungsten carbide at percentages targeted to further enhance the abrasion resistance of the alloy and target the specific wear mode.

Lower hardness materials are machinable and can be applied to high carbon base materials without becoming hard and brittle which makes them an excellent choice for cast iron and mold repair.

Applications

- BUSHINGS

- SLEEVES

- FEED SCREWS

- PLUNGERS

- RODS

- PUMP SHAFTS

- CHROME REPLACEMENT

- HYDRAULIC PISTONS

- GLASS MOLD

- BRICK MOLDS

- EARTH ENGAGING TOOLS

- STABILIZERS

- WEAR PADS

- FORMING DIES

- PUMP REPAIR

- ROCKER ARMS

- STEAM VALVES

- SCREW CONVEYORS

- MIXER BLADES

- FAN BLADES

- ROLLING MILLS

Self Fluxing Nickel Alloys

| Ni | C | SI | CR | B | FE | P | Cu | Mo | W | HRC | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SP18 | Bal. | < 0.1 | 0.5 | 1 | 2 | 15-22 | |||||

| SP22 | Bal. | < 0.1 | 2.3 | 1.5 | 0 | 20-28 | |||||

| SP25 | Bal. | < 0.1 | 1 | 1 | 2 | 22-30 | |||||

| SP26 | Bal. | < 0.1 | 1.5 | 1.5 | 1 | 1 | 1.8 | 22-28 | |||

| SP28 | Bal. | < 0.1 | 2.2 | 2.5 | 1 | 1 | 2 | 26-32 | |||

| SP30 Cu | Bal. | < 0.1 | 2.5 | 3 | 1.5 | 2.5 | 20 | 26-33 | |||

| SP30 PCr | Bal. | < 0.1 | 2.5 | 3 | 1.5 | 2.5 | 2 | 28-35 | |||

| SP30Cr | Bal. | < 0.1 | 2.5 | 3 | 1.5 | 2.5 | 28-35 | ||||

| SP30P | Bal. | < 0.1 | 2.5 | 1.5 | 2.5 | 2 | 26-33 | ||||

| SP30 | Bal. | < 0.1 | 2.5 | 1.5 | 2.5 | 26-33 | |||||

| SP40 | Bal. | < 0.1 | 3 | 2 | 2.5 | 33-40 | |||||

| SP40P | Bal. | < 0.1 | 3 | 2 | 2.5 | 2.5 | 33-40 | ||||

| SP42 | Bal. | 0.1-0.4 | 2.5 | 6 | 2 | 3 | 33-40 | ||||

| SP44 | Bal. | 0.2-0.6 | 2.5 | 8 | 2 | 2.5 | 35-42 | ||||

| SP45 | Bal. | 0.4-0.8 | 3 | 10 | 2.5 | 4 | 40-48 | ||||

| SP46 | Bal. | 0.5-0.1 | 4 | 15 | 3.5 | 4 | 56-62 | ||||

| SP50 | Bal. | < 0.1 | 4.5 | 3 | <4 | 45-50 | |||||

| SP55 | Bal. | 0.5-1.0 | 4 | 15 | 3.5 | 4 | 3 | 3 | 56-62 | ||

| SP56 | Bal. | 0.4-0.8 | 2.8 | 12 | 2.8 | 3 | 48-54 | ||||

| SP57 | Bal. | 0.4-0.8 | 2.8 | 12 | 2.8 | 4 | 3 | 2 | 48-54 | ||

| SP72 | Bal. | 0.5-0.1 | 4 | 12 | 3.5 | 4 | 10 | 55-60 | |||

| SP77 | Bal. | < 0.1 | 4.5 | 7 | 3 | <1 | 45-55 | ||||

| SP78 | Bal. | < 0.1 | 4.5 | 3.3 | <1 | 40-50 | |||||

| SP88 | Bal. | 0.5-1 | 4 | 14 | 3.5 | 4 | 14 | 57-63 | |||

| SP99 | Bal. | 0.5- 1 | 4 | 14 | 3.5 | 4 | 3 | 12 | 57-63 |

Nickel Alloys

| Ni | C | SI | CR | B | FE | P | Cu | Mo | W | HRC | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NIA-622 | Bal. | <0.01 | 21.5 | 4 | 0.025 | 13.5 | 3 | ||||

| NIA-625 | Bal. | <0.01 | 21 | 8.5 | |||||||

| NIA718 | Bal. | – | – | 21.5 | 4 | 13.5 | 3 | ||||

| NIA-C | Bal. | 0.1 | <1.0 | 17 | 6 | 17 | 5 | 17-27 |